roller chains with extended pins assembled from our spanish distributor www.dreizon.com

ropl

| Teilung |

|

|

|

|

|

|

|

W |

T1 |

T2 |

Ø |

B |

T3 |

| mm |

mm |

mm |

mm |

mm |

mm |

mm |

| 142 |

50 |

28 |

62 |

25 |

30 |

15 |

| 142 |

50 |

19 |

42 |

25 |

20 |

11 |

| 160 |

50 |

23 |

50 |

25 |

25 |

13 |

| 260 |

75 |

31 |

70 |

32 |

33 |

20 |

| Teilung |

|

|

|

|

|

|

|

W |

T1 |

T2 |

Ø |

B |

T3 |

| mm |

mm |

mm |

mm |

mm |

mm |

mm |

| 142 |

50 |

28 |

62 |

25 |

30 |

15 |

| 142 |

50 |

19 |

42 |

25 |

20 |

11 |

| 160 |

50 |

23 |

50 |

25 |

25 |

13 |

| 260 |

75 |

31 |

70 |

32 |

33 |

20 |

| Teilung |

|

|

|

|

|

|

|

|

|

W |

T2 |

T4 |

T1 |

C |

Ø |

B |

T3 |

| mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

| 142 |

50 |

42 |

70 |

19 |

12 |

25 |

20 |

11 |

| 142 |

50 |

62 |

87 |

28 |

12 |

25 |

30 |

15 |

| 160 |

50 |

50 |

82 |

23 |

13 |

25 |

25 |

13 |

| 200 |

50 |

60 |

81 |

25 |

12 |

25 |

27 |

18 |

| 250 |

60 |

70 |

95 |

30 |

13 |

30 |

32 |

20 |

standard available in following materials:

20MnCr5 Case Hardening

16MnCr5 Case Hardening

C40 Hardening & Tempering

42CrMo4 Hardening & Tempering

Pin:

20MnCr5

16MnCr5

C40

SS 420

SS 304

circlip:

St 37.2

SS 420

SS 304

We welcome your own Design or other Dimensions! ask us!

chain wear gauge

sprockets for round link chains acc. to DIN766 thickness 11 – 23mm

| thickness |

pitch |

No. of teeth |

pitch circle Ø |

tip circle Ø |

rim width |

pilot bore |

hubØ |

hub-dia. |

weight |

| w |

p |

|

D1 |

D |

BK |

|

DN |

|

kg/pcs. |

| mm |

mm |

|

mm |

mm |

mm |

mm |

mm |

mm |

|

| 11 |

31 |

5 |

99 |

124 |

56 |

30 |

90 |

70 |

3,50 |

| 11 |

31 |

6 |

119 |

165 |

56 |

30 |

90 |

70 |

5,50 |

| 11 |

31 |

7 |

138 |

165 |

56 |

30 |

90 |

70 |

6,50 |

| 11 |

31 |

8 |

160 |

200 |

56 |

30 |

90 |

70 |

7,00 |

| 11 |

31 |

10 |

197 |

240 |

56 |

30 |

90 |

70 |

9,00 |

| 11 |

31 |

12 |

237 |

270 |

60 |

30 |

90 |

75 |

12,00 |

| 11 |

31 |

14 |

276 |

300 |

60 |

30 |

90 |

75 |

13,00 |

| 11 |

31 |

16 |

316 |

346 |

60 |

30 |

90 |

75 |

16,00 |

| 11 |

31 |

18 |

356 |

390 |

60 |

30 |

90 |

75 |

22,00 |

| 13 |

36 |

5 |

115 |

155 |

68 |

30 |

100 |

75 |

5,50 |

| 13 |

36 |

6 |

138 |

186 |

68 |

30 |

100 |

88 |

8,50 |

| 13 |

36 |

7 |

160 |

206 |

68 |

30 |

100 |

75 |

10,00 |

| 13 |

36 |

9 |

207 |

243 |

68 |

35 |

100 |

75 |

12,00 |

| 13 |

36 |

11 |

252 |

270 |

68 |

35 |

100 |

75 |

14,00 |

| 13 |

36 |

12 |

275 |

300 |

72 |

35 |

100 |

75 |

15,00 |

| 13 |

36 |

14 |

321 |

370 |

72 |

35 |

100 |

80 |

24,00 |

| 13 |

36 |

15 |

344 |

390 |

72 |

35 |

140 |

80 |

29,00 |

| 13 |

36 |

28 |

642 |

692 |

72 |

50 |

180 |

155 |

84,00 |

| 14 |

41 |

8 |

202 |

250 |

70 |

40 |

140 |

70 |

15,00 |

| 16 |

45 |

5 |

146 |

190 |

82 |

30 |

110 |

90 |

10,00 |

| 16 |

45 |

6 |

172 |

225 |

82 |

40 |

110 |

90 |

13,00 |

| 16 |

45 |

7 |

201 |

250 |

82 |

30 |

130 |

90 |

17,00 |

| 16 |

45 |

8 |

229 |

278 |

82 |

40 |

110 |

90 |

18,00 |

| 16 |

45 |

10 |

286 |

326 |

82 |

40 |

180 |

90 |

30,00 |

| 18 |

50 |

6 |

191 |

250 |

88 |

40 |

120 |

95 |

18,00 |

| 18 |

50 |

8 |

255 |

310 |

88 |

40 |

120 |

95 |

32,00 |

| 18 |

50 |

9 |

287 |

330 |

88 |

40 |

120 |

95 |

45,00 |

| 20 |

56 |

6 |

214 |

285 |

100 |

50 |

140 |

110 |

24,00 |

| 20 |

56 |

8 |

285 |

320 |

100 |

50 |

140 |

110 |

32,00 |

| 23 |

64 |

8 |

326 |

390 |

120 |

60 |

160 |

130 |

48,00 |

sprockets for round link chains acc. to DIN766 thickness 7 – 10mm

| thickness |

pitch |

No. of teeth |

pitch circle Ø |

tip circle Ø |

rim width |

pilot bore |

hubØ |

hub-dia. |

weight |

| w |

p |

|

D1 |

D |

BK |

|

DN |

|

kg/pcs.

|

| mm |

mm |

|

mm |

mm |

mm |

mm |

mm |

mm |

|

| 7 |

22 |

6 |

84 |

110 |

38 |

– |

60 |

60 |

2,30 |

| 7 |

22 |

9 |

126 |

153 |

38 |

– |

80 |

60 |

4,00 |

| 7 |

22 |

10 |

140 |

157 |

38 |

– |

80 |

60 |

4,00 |

| 7 |

22 |

12 |

168 |

190 |

38 |

20 |

80 |

65 |

4,50 |

| 7 |

22 |

14 |

196 |

230 |

38 |

25 |

80 |

65 |

6,00 |

| 7 |

22 |

16 |

224 |

258 |

40 |

20 |

80 |

60 |

7,00 |

| 8 |

24 |

5 |

76 |

105 |

45 |

– |

80 |

65 |

2,30 |

| 8 |

24 |

6 |

92 |

115 |

45 |

– |

80 |

65 |

3,00 |

| 8 |

24 |

7 |

107 |

117 |

45 |

– |

80 |

65 |

3,40 |

| 8 |

24 |

8 |

122 |

162 |

45 |

– |

80 |

65 |

4,60 |

| 8 |

24 |

10 |

153 |

180 |

45 |

25 |

80 |

65 |

4,80 |

| 8 |

24 |

12 |

183 |

212 |

48 |

25 |

80 |

65 |

6,00 |

| 8 |

24 |

14 |

214 |

245 |

48 |

25 |

80 |

65 |

7,50 |

| 8 |

24 |

16 |

244 |

275 |

48 |

25 |

90 |

70 |

9,00 |

| 8 |

24 |

18 |

275 |

305 |

48 |

25 |

90 |

70 |

11,00 |

| 8 |

24 |

20 |

306 |

345 |

48 |

25 |

90 |

70 |

13,00 |

| 8 |

24 |

24 |

367 |

390 |

48 |

30 |

120 |

70 |

15,00 |

| 8 |

24 |

28 |

428 |

450 |

48 |

25 |

120 |

70 |

17,00 |

| 8 |

24 |

30 |

458 |

495 |

48 |

30 |

120 |

70 |

19,00 |

| 8 |

24 |

32 |

489 |

530 |

48 |

30 |

90 |

70 |

21,00 |

| 8 |

24 |

38 |

581 |

610 |

50 |

25 |

100 |

75 |

25,00 |

| 9 |

27 |

6 |

103 |

140 |

52 |

– |

80 |

65 |

3,80 |

| 9 |

27 |

8 |

138 |

160 |

52 |

20 |

80 |

65 |

5,00 |

| 9 |

27 |

10 |

172 |

205 |

52 |

20 |

80 |

65 |

6,00 |

| 9 |

27 |

12 |

206 |

250 |

52 |

30 |

80 |

65 |

8,00 |

| 10 |

28 |

5 |

89 |

115 |

50 |

– |

60 |

65 |

3,00 |

| 10 |

28 |

8 |

140 |

170 |

50 |

25 |

80 |

65 |

6,50 |

| 10 |

28 |

12 |

214 |

250 |

52 |

25 |

140 |

75 |

14,00 |

| 10 |

28 |

24 |

428 |

450 |

56 |

30 |

100 |

70 |

19,00 |

Sprockets for round link chains acc. to DIN 766

| thickness |

pitch |

No. of teeth |

pitch circle Ø |

tip circle Ø |

rim width |

pilot bore |

hubØ |

hub-dia. |

weight |

| w |

p |

|

D1 |

D |

BK |

|

DN |

|

kg/pcs. |

| mm |

mm |

|

mm |

mm |

mm |

mm |

mm |

mm |

|

| 4 |

16 |

4 |

41 |

56 |

23 |

– |

40 |

30 |

0,30 |

| 4 |

16 |

8 |

81 |

96 |

23 |

– |

50 |

35 |

1,00 |

| 4 |

16 |

12 |

122 |

140 |

23 |

– |

50 |

40 |

1,50 |

| 4 |

16 |

15 |

153 |

165 |

23 |

– |

50 |

40 |

2,40 |

| 4 |

16 |

18 |

183 |

200 |

23 |

– |

50 |

40 |

2,60 |

| 5 / 6 |

18,5 |

6 |

71 |

95 |

32 |

– |

50 |

50 |

1,20 |

| 5 / 6 |

18,5 |

7 |

82 |

110 |

32 |

– |

60 |

50 |

1,90 |

| 5 / 6 |

18,5 |

8 |

94 |

120 |

32 |

– |

50 |

50 |

2,00 |

| 5 / 6 |

18,5 |

10 |

118 |

135 |

32 |

– |

60 |

50 |

2,40 |

| 5 / 6 |

18,5 |

12 |

141 |

165 |

32 |

– |

60 |

50 |

3,20 |

| 5 / 6 |

18,5 |

14 |

165 |

185 |

32 |

– |

65 |

50 |

3,90 |

| 5 / 6 |

18,5 |

15 |

177 |

200 |

32 |

– |

65 |

50 |

3,20 |

| 5 / 6 |

18,5 |

16 |

188 |

215 |

32 |

– |

60 |

50 |

3,80 |

| 5 / 6 |

18,5 |

18 |

212 |

235 |

32 |

– |

60 |

50 |

5,00 |

| 5 / 6 |

18,5 |

19 |

224 |

250 |

32 |

– |

60 |

55 |

5,00 |

| 5 / 6 |

18,5 |

20 |

236 |

260 |

32 |

– |

60 |

50 |

4,50 |

| 5 / 6 |

18,5 |

24 |

283 |

300 |

32 |

– |

60 |

50 |

5,20 |

| 5 / 6 |

18,5 |

26 |

306 |

335 |

32 |

– |

70 |

60 |

7,20 |

| 5 / 6 |

18,5 |

28 |

330 |

360 |

32 |

– |

70 |

60 |

7,10 |

| 5 / 6 |

18,5 |

30 |

353 |

380 |

34 |

– |

70 |

60 |

9,00 |

| 5 / 6 |

18,5 |

32 |

377 |

400 |

34 |

– |

70 |

60 |

10,50 |

| 5 / 6 |

18,5 |

34 |

400 |

435 |

34 |

– |

70 |

60 |

10,00 |

| 5 / 6 |

18,5 |

36 |

424 |

450 |

34 |

25 |

80 |

70 |

12,00 |

| 5 / 6 |

18,5 |

38 |

448 |

480 |

34 |

25 |

80 |

70 |

14,00 |

| 5 / 6 |

18,5 |

40 |

470 |

500 |

38 |

25 |

100 |

75 |

17,00 |

| 5 / 6 |

18,5 |

43 |

503 |

530 |

38 |

25 |

90 |

80 |

18,00 |

| 5 / 6 |

18,5 |

45 |

530 |

570 |

38 |

25 |

90 |

75 |

19,00 |

| 5 / 6 |

18,5 |

50 |

589 |

620 |

38 |

25 |

100 |

70 |

25,00 |

| 5 / 6 |

18,5 |

60 |

707 |

732 |

40 |

30 |

100 |

90 |

31,00 |

| 5 / 6 |

18,5 |

65 |

766 |

810 |

40 |

35 |

155 |

75 |

46,00 |

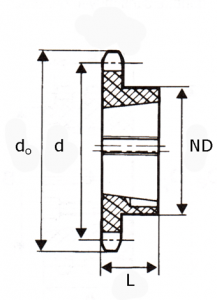

- ISO-Nr.: 06B-1 (3/8“ x 7/32“)

- pitch: 9,525 mm

- inner width: 5,72 mm

- roller-dia.: 6,35 mm

- tooth width: 5,3 mm

- ba 1 mm (radius width)

- rx 10 mm (min. tooth radius)

- hardened teeth (45-55HRC)

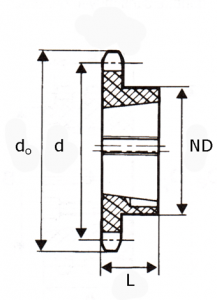

| No. of teeth |

pitch circle |

tip circle |

hub-dia. |

total length |

for |

| z |

d |

do |

ND |

L |

bush |

| 17 |

51,83 |

55,3 |

45 |

22 |

1008 |

| 19 |

57,87 |

61,3 |

45 |

22 |

1008 |

| 21 |

63,91 |

68,0 |

46 |

22 |

1008 |

| 23 |

59,95 |

73,5 |

63 |

25 |

1210 |

| 25 |

76,02 |

80,0 |

63 |

25 |

1210 |

| 27 |

82,02 |

86,0 |

63 |

25 |

1210 |

| 30 |

91,12 |

94,7 |

63 |

25 |

1210 |

The suitable Taper-bushes you will find here.

| Roller Typ |

A |

B |

C |

ØD |

E |

F

max. |

L |

weight approx kg |

suitable to

tensioner |

| RE 2 |

35 |

3,0 |

51 |

30 |

M8 |

7 |

|

0,08 |

|

| RE3 /4 |

45 |

6,0 |

67 |

40 |

M10 |

9 |

|

0,17 |

|

| RE 5 |

60 |

7,5 |

89 |

60 |

M12 |

13 |

|

0,40 |

|

| RE 6 |

90 |

9,0 |

127 |

80 |

M20 |

14 |

|

1,20 |

|

| RE 7 |

135 |

7,0 |

167 |

80 |

M20 |

12 |

|

1,70 |

|

Roller Type RE:

At the beginning as a roating roller for tensioning of flat belts and later developed for tensioning of poly-and V-belts and power belts, the roller type RE is widely used as a universal machine component.

Would you like to change the material, other diameter or profiling? Please clarify the possibilities with us.

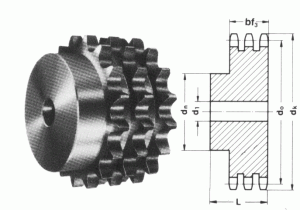

- ISO-No.: 05B-2 (8 x 3mm)

- pitch: 8 mm

- inner width: 3 mm

- Roller-dia.: 5 mm

- tooth width bf2 8,3 mm

- ba 1,0 mm (radius width)

- rx 8,0 mm (min. tooth radius)

| No. of teeth |

pitch circle |

tip circle |

pilot bore |

weight |

|

Ø |

Ø |

Ø |

approx |

|

d0 |

dk |

d1 |

kg |

|

|

|

|

|

| 8 |

20,90 |

24,0 |

6 |

0,01 |

| 9 |

23,39 |

26,6 |

6 |

0,01 |

|

|

|

|

|

| 10 |

25,89 |

29,2 |

8 |

0,02 |

| 11 |

28,39 |

31,7 |

8 |

0,02 |

| 12 |

30,91 |

34,2 |

8 |

0,03 |

| 13 |

33,42 |

36,7 |

8 |

0,04 |

| 14 |

35,95 |

39,2 |

8 |

0,05 |

|

|

|

|

|

| 15 |

38,48 |

41,7 |

8 |

0,06 |

| 16 |

41,01 |

44,3 |

10 |

0,07 |

| 17 |

43,53 |

46,8 |

10 |

0,08 |

| 18 |

46,07 |

49,3 |

10 |

0,09 |

| 19 |

48,61 |

51,9 |

10 |

0,10 |

|

|

|

|

|

| 20 |

51,14 |

54,4 |

10 |

0,11 |

| 21 |

53,67 |

57,0 |

10 |

0,13 |

| 22 |

56,21 |

59,5 |

10 |

0,14 |

| 23 |

58,75 |

62,0 |

10 |

0,16 |

| 24 |

61,29 |

64,6 |

10 |

0,17 |

|

|

|

|

|

| 25 |

63,83 |

67,5 |

10 |

0,18 |

| 26 |

66,37 |

69,5 |

12 |

0,19 |

| 27 |

68,91 |

72,2 |

12 |

0,20 |

| 28 |

71,45 |

74,8 |

12 |

0,22 |

| 29 |

73,99 |

77,3 |

12 |

0,23 |

|

|

|

|

|

| 30 |

76,53 |

79,8 |

12 |

0,25 |

| 31 |

79,08 |

82,4 |

12 |

0,27 |

| 32 |

81,61 |

84,9 |

12 |

0,29 |

| 33 |

84,16 |

87,5 |

12 |

0,32 |

| 34 |

86,70 |

90,0 |

12 |

0,34 |

|

|

|

|

|

| 35 |

89,24 |

92,5 |

12 |

0,36 |

| 36 |

97,79 |

95,0 |

12 |

0,38 |

| 37 |

94,33 |

97,6 |

12 |

0,40 |

| 38 |

96,88 |

100,2 |

12 |

0,42 |

| 39 |

99,42 |

102,7 |

12 |

0,44 |

|

|

|

|

|

| 40 |

101,97 |

105,2 |

12 |

0,47 |

| 41 |

104,51 |

107,8 |

14 |

0,49 |

| 42 |

107,05 |

110,4 |

14 |

0,51 |

| 43 |

109,60 |

112,9 |

14 |

0,54 |

| 44 |

112,14 |

115,5 |

14 |

0,57 |

|

|

|

|

|

| 45 |

114,69 |

118,0 |

14 |

0,60 |

| 46 |

117,23 |

120,6 |

14 |

0,63 |

| 47 |

119,77 |

123,1 |

14 |

0,66 |

| 48 |

122,32 |

125,6 |

14 |

0,69 |

| 49 |

124,86 |

128,2 |

14 |

0,72 |

|

|

|

|

|

| 50 |

127,41 |

130,7 |

14 |

0,75 |

| 51 |

129,95 |

133,3 |

16 |

0,78 |

| 52 |

132,49 |

135,8 |

16 |

0,82 |

| 53 |

135,04 |

138,4 |

16 |

0,85 |

| 54 |

137,59 |

140,9 |

16 |

0,90 |

|

|

|

|

|

| 55 |

140,13 |

143,5 |

16 |

0,93 |

| 56 |

142,68 |

146,0 |

16 |

0,96 |

| 57 |

145,22 |

148,6 |

16 |

0,99 |

| 58 |

147,77 |

151,0 |

16 |

1,03 |

| 59 |

150,31 |

153,6 |

16 |

1,,07 |

|

|

|

|

|

| 60 |

152,85 |

156,2 |

16 |

1,11 |

| 62 |

157,95 |

162,0 |

20 |

1,17 |

| 64 |

163,04 |

167,1 |

20 |

1,24 |

| 65 |

165,58 |

169,2 |

20 |

1,30 |

| 66 |

168,13 |

172,2 |

20 |

1,36 |

|

|

|

|

|

| 68 |

173,22 |

177,3 |

20 |

1,44 |

| 70 |

178,31 |

182,4 |

20 |

1,51 |

| 72 |

183,41 |

187,5 |

20 |

1,63 |

| 75 |

191,04 |

195,1 |

20 |

1,72 |

| 76 |

193,59 |

197,7 |

20 |

1,80 |

|

|

|

|

|

| 78 |

198,68 |

202,8 |

20 |

1,90 |

| 80 |

203,77 |

207,9 |

20 |

2,00 |

| 85 |

216,50 |

220,6 |

20 |

2,50 |

| 90 |

229,23 |

233,4 |

20 |

3,00 |

| 95 |

241,96 |

246,1 |

20 |

3,20 |

|

|

|

|

|

| 100 |

254,68 |

258,9 |

20 |

3,50 |

| 110 |

280,15 |

284,3 |

20 |

3,75 |

| 114 |

290,33 |

294,5 |

20 |

4,15 |

| 120 |

305,61 |

310,0 |

20 |

4,65 |

| 125 |

318,34 |

322,5 |

20 |

5,50 |

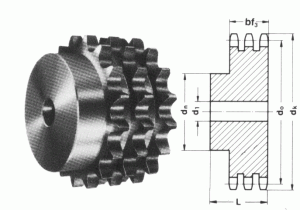

- ISO-No.: ASA40-3 = 08A-3 (1/2“ x 5/16“)

- pitch: 12,7 mm

- inner width: 7,94 mm

- Roller-dia.: 7,94 mm

- tooth width bf3: 36 mm

- ba 1,6 mm (radius width)

- rx 13,5 mm (min. tooth radius)

| No. of teeth |

pitch circle |

tip circle |

hub |

pilot bore |

bore |

total |

weight |

|

Ø |

Ø |

Ø |

Ø |

max. |

length |

approx |

| Material steel/C45 |

do |

dk |

dn |

d1 |

d2 |

L |

kg |

| 12 |

49,10 |

53,0 |

35 |

14 |

22 |

50 |

0,39 |

| 13 |

53,10 |

57,0 |

38 |

14 |

24 |

50 |

0,49 |

| 14 |

57,10 |

62,0 |

42 |

14 |

27 |

50 |

0,60 |

|

|

|

|

|

|

|

|

| 15 |

61,10 |

66,0 |

46 |

14 |

28 |

50 |

0,72 |

| 16 |

65,10 |

70,0 |

50 |

16 |

31 |

50 |

0,85 |

| 17 |

69,10 |

74,0 |

54 |

16 |

33 |

50 |

0,99 |

| 18 |

73,10 |

78,0 |

58 |

16 |

36 |

50 |

1,14 |

| 19 |

77,20 |

82,0 |

62 |

16 |

38 |

50 |

1,30 |

|

|

|

|

|

|

|

|

| 20 |

81,20 |

86,0 |

66 |

16 |

41 |

50 |

1,47 |

| 21 |

85,20 |

90,0 |

70 |

20 |

44 |

55 |

1,79 |

| 22 |

89,20 |

94,0 |

70 |

20 |

44 |

55 |

1,93 |

| 23 |

93,30 |

98,0 |

70 |

20 |

44 |

55 |

2,08 |

| 24 |

98,30 |

102,0 |

75 |

20 |

46 |

55 |

2,32 |

|

|

|

|

|

|

|

|

| 25 |

101,30 |

106,0 |

80 |

20 |

50 |

55 |

2,57 |

| 26 |

105,40 |

110,0 |

85 |

20 |

53 |

55 |

2,79 |

| 27 |

109,40 |

114,0 |

85 |

20 |

53 |

55 |

2,96 |

| 28 |

113,40 |

118,0 |

90 |

20 |

56 |

55 |

3,25 |

- ISO-No.: sprockets ASA35-2 (3/8“ x 3/16“)

- pitch: 9,525 mm

- inner width: 4,77 mm

- Roller-dia: 5,08 mm

- tooth width bf2 14,4 mm

- ba 1,2 mm (radius width)

- rx 10 mm (min. tooth radius)

| No. of teeth |

pitch circle |

tip circle |

hub |

pilot bore |

bore |

total |

weight |

|

Ø |

Ø |

Ø |

Ø |

max. |

length |

approx |

| z |

do |

dk |

dn |

d1 |

d2 |

L |

kg |

|

|

|

|

|

|

|

|

| 13 |

39,79 |

43,0 |

28 |

10 |

18 |

25 |

0,16 |

| 14 |

42,80 |

46,3 |

31 |

10 |

20 |

25 |

0,20 |

|

|

|

|

|

|

|

|

| 15 |

45,81 |

49,3 |

34 |

10 |

22 |

25 |

0,24 |

| 16 |

48,82 |

52,3 |

37 |

12 |

22 |

30 |

0,27 |

| 17 |

51,83 |

55,3 |

40 |

12 |

25 |

30 |

0,32 |

| 18 |

54,85 |

58,3 |

43 |

12 |

27 |

30 |

0,38 |

| 19 |

57,87 |

61,3 |

46 |

12 |

28 |

30 |

0,42 |

|

|

|

|

|

|

|

|

| 20 |

60,89 |

64,3 |

49 |

12 |

30 |

30 |

0,48 |

| 21 |

63,91 |

68,0 |

52 |

12 |

32 |

30 |

0,52 |

| 22 |

66,93 |

71,0 |

55 |

12 |

34 |

30 |

0,58 |

| 23 |

69,95 |

73,5 |

58 |

12 |

36 |

30 |

0,64 |

| 24 |

72,97 |

77,0 |

61 |

12 |

38 |

30 |

0,71 |

|

|

|

|

|

|

|

|

| 25 |

76,00 |

80,0 |

64 |

12 |

40 |

30 |

0,79 |

| 26 |

79,02 |

83,0 |

67 |

12 |

43 |

30 |

0,87 |

| 27 |

82,05 |

86,0 |

70 |

12 |

44 |

30 |

0,94 |

| 28 |

85,07 |

89,0 |

73 |

12 |

45 |

30 |

1,03 |

sprockets ASA35-2 (06C-2)

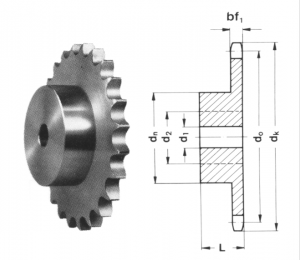

- ISO-no.: sprockets ASA25-1 (6,35 x 3,18mm)

- pitch: 6,35 mm

- inner width: 3,18 mm

- Roller-dia.: 3,3 mm

- tooth width bf1 2,9 mm

- ba 0,6 mm (radius width)

- rx 6 mm (min. tooth radius)

|

No. of teeth

|

pitch circle

|

tip circle

|

hub |

pilot bore |

bore

|

total |

weight |

|

|

Ø

|

Ø

|

Ø

|

Ø

|

max.

|

length

|

approx

|

|

z

|

d0

|

dk

|

dn

|

d1

|

d2

|

L

|

kg

|

|

|

|

|

|

|

|

|

| 10 |

20,55 |

22,30 |

12 |

6 |

7 |

15 |

0,02 |

| 11 |

22,54 |

24,30 |

14 |

6 |

9 |

15 |

0,02 |

| 12 |

24,53 |

26,40 |

16 |

6 |

10 |

15 |

0,03 |

| 13 |

26,53 |

28,50 |

18 |

6 |

11 |

15 |

0,03 |

| 14 |

28,53 |

30,50 |

20 |

6 |

12 |

15 |

0,04 |

|

|

|

|

|

|

|

|

| 15 |

30,55 |

32,50 |

22 |

6 |

13 |

15 |

0,05 |

| 16 |

32,55 |

34,50 |

24 |

8 |

14 |

15 |

0,06 |

| 17 |

34,55 |

36,50 |

26 |

8 |

16 |

15 |

0,07 |

| 18 |

36,56 |

38,50 |

28 |

8 |

17 |

15 |

0,08 |

| 19 |

38,58 |

40,50 |

30 |

8 |

18 |

15 |

0,09 |

|

|

|

|

|

|

|

|

| 20 |

40,58 |

42,50 |

32 |

8 |

20 |

15 |

0,10 |

| 21 |

42,60 |

44,60 |

34 |

8 |

21 |

15 |

0,11 |

| 22 |

44,62 |

46,60 |

36 |

8 |

23 |

15 |

0,12 |

| 23 |

46,63 |

48,60 |

38 |

8 |

24 |

15 |

0,14 |

| 24 |

48,64 |

50,60 |

40 |

8 |

25 |

18 |

0,18 |

|

|

|

|

|

|

|

|

| 25 |

50,66 |

52,60 |

42 |

8 |

26 |

18 |

0,20 |

| 27 |

54,69 |

56,60 |

46 |

10 |

28 |

18 |

0,22 |

| 28 |

56,71 |

58,70 |

48 |

10 |

28 |

18 |

0,25 |

| 30 |

60,75 |

62,70 |

48 |

10 |

28 |

18 |

0,27 |

| 32 |

64,78 |

66,70 |

50 |

12 |

31 |

18 |

0,28 |

|

|

|

|

|

|

|

|

| 34 |

68,82 |

70,80 |

50 |

12 |

31 |

18 |

0,29 |

| 35 |

70,84 |

72,80 |

50 |

12 |

31 |

18 |

0,30 |

| 36 |

72,85 |

74,80 |

50 |

12 |

31 |

18 |

0,31 |

The suitable chain for these sprockets you will find here.

technical details for pre-finished sprockets 06B-1:

- ISO-no.: 06B-1 (3/8“ x 7/32“)

- Roller-diameter : 6,35 mm

- rx 10 mm (min. tooth radius)

- hardened teeth (45-55HRC)

- keyway acc. to DIN 6885/1

- 1 x screwbore on keyway + 1 x screw bore 90°

|

sprockets 06B-1

|

pitch circle

|

tip circle

|

hub

|

bore |

width of keyway

acc. to DIN6885/1

|

total

|

screw-type |

|

No. of teeth

|

Ø

|

Ø

|

Ø

|

Ø

|

|

length

|

|

|

z

|

d0

|

dk

|

d

|

D |

b

|

H |

|

|

|

|

|

|

|

|

|

|

Material steel/C45

|

|

|

|

|

|

|

|

| 10 |

30,82 |

34,0 |

24* |

10 |

3 |

22 |

M3 |

|

|

|

24* |

11 |

4 |

22 |

M3 |

|

|

|

26* |

12 |

4 |

22 |

M3 |

|

|

|

29* |

14 |

5 |

22 |

M4 |

|

|

|

|

|

|

|

|

| 11 |

33,81 |

37,0 |

24 |

10 |

3 |

25 |

M3 |

|

|

|

26* |

12 |

4 |

25 |

M3 |

|

|

|

29* |

14 |

5 |

25 |

M4 |

|

|

|

30* |

15 |

5 |

25 |

M4 |

|

|

|

31* |

16 |

5 |

25 |

M4 |

|

|

|

|

|

|

|

|

| 12 |

36,80 |

40,0 |

25 |

10 |

3 |

25 |

M3 |

|

|

|

26 |

12 |

4 |

25 |

M3 |

|

|

|

29* |

14 |

4 |

25 |

M4 |

|

|

|

30* |

15 |

5 |

25 |

M4 |

|

|

|

31* |

16 |

5 |

25 |

M4 |

|

|

|

|

|

|

|

|

| 13 |

39,79 |

43,0 |

28 |

10 |

3 |

25 |

M3 |

|

|

|

28 |

12 |

4 |

25 |

M3 |

|

|

|

29 |

14 |

4 |

25 |

M3 |

|

|

|

30 |

15 |

5 |

25 |

M4 |

|

|

|

31* |

16 |

5 |

25 |

M4 |

|

|

|

35* |

18 |

6 |

25 |

M5 |

|

|

|

|

|

|

|

|

| 14 |

42,81 |

46,0 |

31 |

12 |

4 |

25 |

M3 |

|

|

|

31 |

14 |

4 |

25 |

M3 |

|

|

|

31 |

15 |

5 |

25 |

M4 |

|

|

|

31 |

16 |

5 |

25 |

M4 |

|

|

|

35* |

18 |

6 |

25 |

M5 |

|

|

|

35* |

19 |

6 |

25 |

M5 |

|

|

|

|

|

|

|

|

| 15 |

45,81 |

49,3 |

34 |

12 |

4 |

25 |

M3 |

|

|

|

34 |

14 |

4 |

25 |

M3 |

|

|

|

34 |

15 |

5 |

25 |

M4 |

|

|

|

34 |

16 |

5 |

25 |

M4 |

|

|

|

34 |

18 |

6 |

25 |

M5 |

|

|

|

35 |

19 |

6 |

25 |

M5 |

|

|

|

36 |

20 |

6 |

25 |

M5 |

|

|

|

38* |

22 |

6 |

25 |

M5 |

|

|

|

42* |

24 |

8 |

25 |

M6 |

|

|

|

42* |

25 |

8 |

25 |

M6 |

|

|

|

|

|

|

|

|

| 16 |

48,82 |

52,0 |

37 |

12 |

4 |

28 |

M3 |

|

|

|

37 |

14 |

4 |

28 |

M3 |

|

|

|

37 |

15 |

5 |

28 |

M4 |

|

|

|

37 |

16 |

5 |

28 |

M4 |

|

|

|

37 |

18 |

6 |

28 |

M5 |

|

|

|

37 |

19 |

6 |

28 |

M5 |

|

|

|

37 |

20 |

6 |

28 |

M5 |

|

|

|

37 |

22 |

6 |

28 |

M5 |

|

|

|

42* |

24 |

8 |

28 |

M6 |

|

|

|

42* |

25 |

8 |

28 |

M6 |

|

|

|

|

|

|

|

|

| 17 |

51,84 |

55,0 |

40 |

12 |

4 |

28 |

M3 |

|

|

|

40 |

14 |

4 |

28 |

M3 |

|

|

|

40 |

15 |

5 |

28 |

M4 |

|

|

|

40 |

16 |

5 |

28 |

M4 |

|

|

|

40 |

18 |

6 |

28 |

M5 |

|

|

|

40 |

19 |

6 |

28 |

M5 |

|

|

|

40 |

20 |

6 |

28 |

M5 |

|

|

|

40 |

22 |

8 |

28 |

M6 |

|

|

|

40 |

24 |

8 |

28 |

M6 |

|

|

|

42 |

25 |

8 |

28 |

M6 |

|

|

|

|

|

|

|

|

| 18 |

54,85 |

58,0 |

43 |

12 |

4 |

28 |

M3 |

|

|

|

43 |

14 |

4 |

28 |

M3 |

|

|

|

43 |

15 |

5 |

28 |

M4 |

|

|

|

43 |

16 |

5 |

28 |

M4 |

|

|

|

43 |

18 |

6 |

28 |

M5 |

|

|

|

43 |

19 |

6 |

28 |

M5 |

|

|

|

43 |

20 |

6 |

28 |

M5 |

|

|

|

43 |

22 |

8 |

28 |

M6 |

|

|

|

43 |

24 |

8 |

28 |

M6 |

|

|

|

43 |

25 |

8 |

28 |

M6 |

|

|

|

|

|

|

|

|

| 19 |

57,87 |

61,0 |

45 |

12 |

4 |

28 |

M3 |

|

|

|

45 |

14 |

4 |

28 |

M3 |

|

|

|

45 |

15 |

5 |

28 |

M4 |

|

|

|

45 |

16 |

5 |

28 |

M4 |

|

|

|

45 |

18 |

6 |

28 |

M5 |

|

|

|

45 |

19 |

6 |

28 |

M5 |

|

|

|

45 |

20 |

6 |

28 |

M5 |

|

|

|

45 |

22 |

8 |

28 |

M6 |

|

|

|

45 |

24 |

8 |

28 |

M6 |

|

|

|

45 |

25 |

8 |

28 |

M6 |

|

|

|

|

|

|

|

|

| 20 |

60,89 |

64,0 |

46 |

12 |

4 |

28 |

M3 |

|

|

|

46 |

14 |

4 |

28 |

M3 |

|

|

|

46 |

15 |

5 |

28 |

M4 |

|

|

|

46 |

16 |

5 |

28 |

M4 |

|

|

|

46 |

18 |

6 |

28 |

M5 |

|

|

|

46 |

19 |

6 |

28 |

M5 |

|

|

|

46 |

20 |

6 |

28 |

M5 |

|

|

|

46 |

22 |

8 |

28 |

M6 |

|

|

|

46 |

24 |

8 |

28 |

M6 |

|

|

|

46 |

25 |

8 |

28 |

M6 |

|

|

|

|

|

|

|

|

| 21 |

63,91 |

68,0 |

48 |

15 |

5 |

28 |

M4 |

|

|

|

48 |

16 |

5 |

28 |

M4 |

|

|

|

48 |

18 |

6 |

28 |

M5 |

|

|

|

48 |

19 |

6 |

28 |

M5 |

|

|

|

48 |

20 |

6 |

28 |

M5 |

|

|

|

48 |

22 |

8 |

28 |

M6 |

|

|

|

48 |

24 |

8 |

28 |

M6 |

|

|

|

48 |

25 |

8 |

28 |

M6 |

|

|

|

|

|

|

|

|

| 22 |

66,93 |

71,0 |

50 |

15 |

5 |

28 |

M4 |

|

|

|

50 |

16 |

5 |

28 |

M4 |

|

|

|

50 |

18 |

6 |

28 |

M5 |

|

|

|

50 |

19 |

6 |

28 |

M5 |

|

|

|

50 |

20 |

6 |

28 |

M5 |

|

|

|

50 |

22 |

8 |

28 |

M6 |

|

|

|

50 |

24 |

8 |

28 |

M6 |

|

|

|

50 |

25 |

8 |

28 |

M6 |

|

|

|

|

|

|

|

|

| 23 |

69,95 |

74,0 |

52 |

15 |

5 |

28 |

M4 |

|

|

|

52 |

16 |

5 |

28 |

M4 |

|

|

|

52 |

18 |

6 |

28 |

M5 |

|

|

|

52 |

19 |

6 |

28 |

M5 |

|

|

|

52 |

20 |

6 |

28 |

M5 |

|

|

|

52 |

22 |

8 |

28 |

M6 |

|

|

|

52 |

24 |

8 |

28 |

M6 |

|

|

|

52 |

25 |

8 |

28 |

M6 |

|

|

|

|

|

|

|

|

| 24 |

72,97 |

77,0 |

54 |

15 |

5 |

28 |

M4 |

|

|

|

54 |

16 |

5 |

28 |

M4 |

|

|

|

54 |

18 |

6 |

28 |

M5 |

|

|

|

54 |

19 |

6 |

28 |

M5 |

|

|

|

54 |

20 |

6 |

28 |

M5 |

|

|

|

54 |

22 |

8 |

28 |

M6 |

|

|

|

54 |

24 |

8 |

28 |

M6 |

|

|

|

54 |

25 |

8 |

28 |

M6 |

|

|

|

|

|

|

|

|

| 25 |

76,00 |

80,0 |

57 |

16 |

5 |

28 |

M4 |

|

|

|

57 |

18 |

6 |

28 |

M5 |

|

|

|

57 |

19 |

6 |

28 |

M5 |

|

|

|

57 |

20 |

6 |

28 |

M5 |

|

|

|

57 |

22 |

8 |

28 |

M6 |

|

|

|

57 |

24 |

8 |

28 |

M6 |

|

|

|

57 |

25 |

8 |

28 |

M6 |

|

|

|

|

|

|

|

|

| 30 |

91,12 |

95,0 |

60 |

20 |

6 |

30 |

M5 |

|

|

|

60 |

22 |

8 |

30 |

M6 |

|

|

|

60 |

24 |

8 |

30 |

M6 |

|

|

|

60 |

25 |

8 |

30 |

M6 |

|

|

|

60 |

28 |

8 |

30 |

M6 |

|

|

|

60 |

30 |

8 |

30 |

M6 |

* type

The suitable chain for these sprockets you will find here.

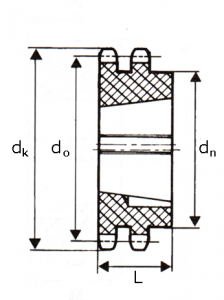

- ISO-Nr.: 06 B-2 (3/8“ x 7/32“)

- pitch: 9,525 mm

- inner width: 5,72 mm

- roller-dia.: 6,35 mm

- Tooth width bf2 15,4 mm

- ba 1 mm (radius width)

- rx 10 mm (min. tooth radius)

- hardened teeth (45-55 HRC)

No. of tooth

|

pitch circle |

tip circle |

hub |

pilot bore

|

bore |

total |

weight |

|

Ø |

Ø |

Ø |

Ø |

max. |

length |

approx |

| z |

do |

dk |

dn |

d1 |

d2 |

L |

kg |

|

|

|

|

|

|

|

|

| 8 |

24,89 |

28,0 |

15 |

6 |

9 |

22 |

0,04 |

| 9 |

27,85 |

31,0 |

18 |

8 |

11 |

22 |

0,05 |

| 10 |

30,82 |

34,0 |

20 |

8 |

12 |

22 |

0,07 |

| 11 |

33,81 |

37,0 |

22 |

10 |

14 |

25 |

0,10 |

| 12 |

36,8 |

40,0 |

25 |

10 |

16 |

25 |

0,13 |

| 13 |

39,79 |

43,0 |

28 |

10 |

18 |

25 |

0,16 |

| 14 |

42,80 |

46,3 |

31 |

10 |

20 |

25 |

0,20 |

|

|

|

|

|

|

|

|

| 15 |

45,81 |

49,3 |

34 |

10 |

22 |

25 |

0,24 |

| 16 |

48,82 |

52,3 |

37 |

12 |

22 |

30 |

0,27 |

| 17 |

51,83 |

55,3 |

40 |

12 |

25 |

30 |

0,32 |

| 18 |

54,85 |

58,3 |

43 |

12 |

27 |

30 |

0,38 |

| 19 |

57,87 |

61,3 |

46 |

12 |

28 |

30 |

0,42 |

|

|

|

|

|

|

|

|

| 20 |

60,89 |

64,3 |

49 |

12 |

30 |

30 |

0,48 |

| 21 |

63,91 |

68,0 |

52 |

12 |

32 |

30 |

0,52 |

| 22 |

66,93 |

71,0 |

55 |

12 |

34 |

30 |

0,58 |

| 23 |

69,95 |

73,5 |

58 |

12 |

36 |

30 |

0,64 |

| 24 |

72,97 |

77,0 |

61 |

12 |

38 |

30 |

0,71 |

|

|

|

|

|

|

|

|

| 25 |

76,00 |

80,0 |

64 |

12 |

40 |

30 |

0,79 |

| 26 |

79,02 |

83,0 |

67 |

12 |

43 |

30 |

0,87 |

| 27 |

82,05 |

86,0 |

70 |

12 |

44 |

30 |

0,94 |

| 28 |

85,07 |

89,0 |

73 |

12 |

45 |

30 |

1,03 |

|

|

|

|

|

|

|

|

| 30 |

91,12 |

94,7 |

79 |

12 |

48 |

30 |

1,20 |

| 32 |

97,17 |

101,3 |

80 |

16 |

48 |

30 |

1,32 |

| 34 |

103,23 |

107,3 |

80 |

16 |

48 |

30 |

1,43 |

| 35 |

106,26 |

110,4 |

80 |

16 |

48 |

30 |

1,49 |

|

|

|

|

|

|

|

|

| 37 |

112,32 |

116,4 |

90 |

16 |

50 |

30 |

1,76 |

| 38 |

115,35 |

119,5 |

90 |

16 |

50 |

30 |

1,81 |

| 39 |

118,37 |

122,5 |

90 |

16 |

50 |

30 |

1,88 |

| 40 |

121,40 |

125,5 |

90 |

16 |

50 |

30 |

1,95 |

- ISO-no.: 04-1 (6 x 2,8mm)

- pitch: 6,0 mm

- inner width: 2,8 mm

- roller-dia. : 4 mm

- tooth width: 2,6 mm

- ba 0,7 mm (radius width)

- rx 6 mm (min. tooth radius)

| No. of teeth |

pitch circle |

tip circle |

pilot bore |

weight |

|

Ø |

Ø |

Ø |

approx |

| z |

d0 |

dk |

d1 |

kg |

|

|

|

|

|

| 8 |

15,67 |

18,0 |

5 |

0,01 |

| 9 |

17,54 |

19,9 |

5 |

0,01 |

|

|

|

|

|

| 10 |

19,42 |

21,7 |

6 |

0,01 |

| 11 |

21,30 |

23,6 |

6 |

0,01 |

| 12 |

23,18 |

25,4 |

6 |

0,01 |

| 13 |

25,05 |

27,3 |

8 |

0,01 |

| 14 |

26,96 |

29,2 |

8 |

0,01 |

|

|

|

|

|

| 15 |

28,86 |

31,1 |

8 |

0,01 |

| 16 |

30,76 |

33,0 |

8 |

0,01 |

| 17 |

32,65 |

35,0 |

8 |

0,01 |

| 18 |

34,55 |

36,9 |

8 |

0,02 |

| 19 |

36,44 |

38,8 |

8 |

0,02 |

|

|

|

|

|

| 20 |

38,34 |

40,7 |

8 |

0,02 |

| 21 |

40,25 |

42,6 |

8 |

0,02 |

| 22 |

42,16 |

44,5 |

8 |

0,03 |

| 23 |

44,06 |

46,4 |

8 |

0,03 |

| 24 |

45,96 |

48,3 |

8 |

0,03 |

|

|

|

|

|

| 25 |

47,87 |

50,2 |

8 |

0,03 |

| 26 |

49,77 |

52,1 |

8 |

0,03 |

| 27 |

51,67 |

54,0 |

8 |

0,04 |

| 28 |

53,58 |

55,9 |

8 |

0,04 |

| 29 |

55,50 |

57,8 |

8 |

0,04 |

|

|

|

|

|

| 30 |

57,42 |

59,8 |

8 |

0,05 |

| 31 |

59,31 |

61,7 |

8 |

0,05 |

| 32 |

61,21 |

63,6 |

8 |

0,05 |

| 33 |

63,11 |

65,5 |

8 |

0,06 |

| 34 |

65,02 |

67,4 |

8 |

0,06 |

|

|

|

|

|

| 35 |

66,93 |

69,3 |

8 |

0,07 |

| 36 |

68,84 |

71,2 |

8 |

0,07 |

| 37 |

70,75 |

73,1 |

8 |

0,07 |

| 38 |

72,66 |

75,0 |

8 |

0,08 |

| 39 |

74,56 |

76,9 |

8 |

0,08 |

|

|

|

|

|

| 40 |

76,47 |

78,9 |

8 |

0,09 |

| 41 |

78,38 |

80,8 |

10 |

0,09 |

| 42 |

80,28 |

82,7 |

10 |

0,10 |

| 43 |

82,19 |

84,7 |

10 |

0,10 |

| 44 |

84,10 |

86,6 |

10 |

0,10 |

|

|

|

|

|

| 45 |

86,01 |

88,5 |

10 |

0,11 |

| 46 |

87,92 |

90,4 |

10 |

0,12 |

| 47 |

89,83 |

92,3 |

10 |

0,12 |

| 48 |

91,74 |

94,2 |

10 |

0,13 |

| 49 |

93,64 |

96,1 |

10 |

0,13 |

|

|

|

|

|

| 50 |

95,55 |

98,0 |

10 |

0,14 |

| 51 |

97,47 |

99,9 |

12 |

0,24 |

| 52 |

99,37 |

101,8 |

12 |

0,25 |

| 53 |

101,27 |

103,7 |

12 |

0,25 |

| 54 |

103,17 |

105,6 |

12 |

0,26 |

|

|

|

|

|

| 55 |

105,08 |

107,6 |

12 |

0,27 |

| 56 |

107,00 |

109,5 |

12 |

0,28 |

| 57 |

108,93 |

111,4 |

12 |

0,29 |

| 58 |

110,82 |

113,3 |

12 |

0,30 |

| 59 |

112,71 |

115,2 |

12 |

0,31 |

|

|

|

|

|

| 60 |

114,62 |

117,1 |

12 |

0,33 |

| 62 |

118,45 |

120,9 |

14 |

0,35 |

| 64 |

122,27 |

124,7 |

14 |

0,37 |

| 65 |

124,18 |

126,6 |

14 |

0,38 |

| 66 |

126,09 |

128,5 |

14 |

0,40 |

|

|

|

|

|

| 68 |

129,91 |

132,4 |

14 |

0,42 |

| 70 |

133,73 |

136,2 |

14 |

0,45 |

| 72 |

137,55 |

140,0 |

14 |

0,48 |

| 75 |

143,28 |

145,7 |

16 |

0,51 |

| 76 |

145,19 |

147,6 |

16 |

0,53 |

|

|

|

|

|

| 78 |

149,01 |

151,5 |

16 |

0,56 |

| 80 |

152,82 |

155,3 |

16 |

0,59 |

| 85 |

162,37 |

164,8 |

16 |

0,67 |

| 90 |

171,92 |

174,4 |

16 |

0,77 |

| 95 |

181,47 |

183,9 |

16 |

0,85 |

|

|

|

|

|

| 100 |

191,01 |

193,5 |

16 |

0,94 |

| 110 |

210,11 |

211,6 |

16 |

1,08 |

| 114 |

217,75 |

220,2 |

16 |

1,23 |

| 120 |

229,20 |

231,7 |

16 |

1,37 |

| 125 |

238,75 |

241,2 |

16 |

1,48 |

technical details for simplex sprockets 06B-1 with hardened teeth:

- ISO-Nr.: 06 B-1 (3/8“ x 7/32“)

- rx 10 mm (min. tooth radius)

- hardened teeth (45-55 HRC)

|

No. of teeth

|

pitch circle |

tip circle

|

hub |

pilot bore

|

bore

|

total

|

weight |

|

Ø

|

Ø

|

Ø

|

Ø

|

max.

|

length

|

approx

|

|

z

|

d0

|

dk

|

dn

|

d1

|

d2

|

L

|

kg

|

|

Material Stahl/C45

|

|

|

|

|

|

|

|

|

12

|

36,80

|

40,0

|

25

|

8

|

16

|

25

|

0,068

|

|

13

|

39,79

|

43,0

|

28

|

10

|

18

|

25

|

0,087

|

|

14

|

42,81

|

46,0

|

31

|

10

|

20

|

25

|

0,11

|

|

15

|

45,81

|

49,3

|

34

|

10

|

22

|

25

|

0,13

|

|

16

|

48,82

|

52,0

|

37

|

10

|

23

|

28

|

0,14

|

|

17

|

51,84

|

55,0

|

40

|

10

|

25

|

28

|

0,15

|

|

18

|

54,85

|

58,0

|

43

|

10

|

27

|

28

|

0,16

|

|

19

|

57,87

|

61,0

|

45

|

10

|

28

|

28

|

0,17

|

|

20

|

60,89

|

64,0

|

46

|

10

|

29

|

28

|

0,18

|

|

21

|

63,91

|

68,0

|

48

|

12

|

30

|

28

|

0,25

|

|

22

|

66,93

|

71,0

|

50

|

12

|

30

|

28

|

0,26

|

|

23

|

69,95

|

74,0

|

52

|

12

|

32

|

28

|

0,27

|

|

24

|

72,97

|

77,0

|

54

|

12

|

34

|

28

|

0,28

|

|

25

|

76,00

|

80,0

|

57

|

12

|

36

|

28

|

0,30

|

|

30

|

91,12

|

95,0

|

60

|

12

|

38

|

30

|

0,45

|

Chandelier chain acc. to DIN 5279

available executions: steel, brass

| nominal thickness |

|

|

|

weight (Mat. steel) |

weight (Mat. brass) |

| s1 |

t1 |

b1 |

b2 |

approx kg/m |

approx kg/100m |

| mm |

mm |

mm |

mm |

|

|

| 0,3 |

10 |

4,5 |

2,4 |

1,2 |

1,3 |

| 0,4 |

12 |

5,0 |

2,4 |

1,9 |

2,1 |

| 0,4 |

14 |

5,0 |

2,4 |

1,8 |

2,0 |

| 0,5 |

15 |

5,5 |

2,5 |

2,6 |

2,8 |

| 0,5 |

18 |

6,5 |

3,5 |

3,1 |

3,4 |

| 0,6 |

17 |

6,0 |

3,2 |

3,1 |

3,4 |

| 0,6 |

16 |

7,0 |

3,0 |

3,8 |

4,1 |

| 0,8 |

19 |

7,0 |

3,4 |

4,8 |

5,3 |

| 1,0 |

21 |

8,0 |

4,0 |

6,5 |

7,0 |

| 1,2 |

22 |

9,5 |

4,2 |

9,5 |

10,5 |

Kugelketten nach DIN 5280

available designs among other things: brass, bright surface, nickel plated or chromed

|

|

|

weight approx |

| type |

d |

t |

kg / 100m |

|

mm |

mm |

|

A = balls with seam

|

2,0 |

2,6 |

1,2 |

|

2,2 |

2,8 |

1,3 |

|

2,5 |

3,2 |

1,8 |

|

2,8 |

3,4 |

2,2 |

|

3,2 |

4,0 |

2,5 |

|

3,6 |

4,5 |

3,2 |

|

4,0 |

5,0 |

3,7 |

|

4,5 |

5,5 |

4,7 |

B = balls without seams

|

3,2 |

4,0 |

2,5 |

|

3,6 |

4,5 |

3,2 |

|

4,5 |

5,5 |

4,7 |

anti-theft chains

Case hardened and electro galvanized steel with red thermoshrunk sleeve.

| nominal thickness |

length |

| mm |

mm |

|

|

| 4,5 |

600 |

| 4,5 |

800 |

| 4,5 |

1000 |

| 6 |

900 |

| 8 |

900 |

| 8 |

1200 |

| 8 |

2000 |

Case hardened alloy steel, electro galvanized with blue thermoshrunk sleeve.

| nominal thickness |

length |

| mm |

mm |

|

|

| 6 |

600 |

| 6 |

800 |

| 6 |

1000 |

| 8 |

800 |

| 8 |

1000 |

| 8 |

1200 |

| 8 |

1500 |

| 10 |

1000 |

| 10 |

1200 |

| 10 |

1500 |

| 10 |

2000 |

sprockets 06B-1 stainless steel acc. to DIN 8187 or ISO/R 606

- ISO-No.: 06 B-1 (3/8“ x 7/32“)

- rx 10 mm (min. tooth radius)

| No. of teeth |

pitch circle

|

tip circle

|

hub

|

pilot bore

|

bore

|

total |

weight

|

|

Ø

|

Ø

|

Ø

|

Ø

|

max.

|

length

|

approx

|

|

t

|

d0

|

dk

|

dn

|

d1

|

d2

|

L

|

kg

|

|

|

|

|

|

|

|

|

|

Material 1.4301 (AISI 304)

|

|

|

|

|

|

|

|

|

13

|

39,79

|

43,0

|

28

|

10

|

18

|

25

|

0,087

|

|

14

|

42,81

|

46,0

|

31

|

10

|

20

|

25

|

0,11

|

|

15

|

45,81

|

49,3

|

34

|

10

|

22

|

25

|

0,13

|

|

16

|

48,82

|

52,0

|

37

|

10

|

23

|

28

|

0,14

|

|

17

|

51,84

|

55,0

|

40

|

10

|

25

|

28

|

0,15

|

|

18

|

54,85

|

58,0

|

43

|

10

|

27

|

28

|

0,16

|

|

19

|

57,87

|

61,0

|

45

|

10

|

28

|

28

|

0,17

|

|

20

|

60,89

|

64,0

|

46

|

10

|

29

|

28

|

0,18

|

|

21

|

63,91

|

68,0

|

48

|

12

|

30

|

28

|

0,25

|

|

22

|

66,93

|

71,0

|

50

|

12

|

30

|

28

|

0,26

|

|

23

|

69,95

|

74,0

|

52

|

12

|

32

|

28

|

0,27

|

|

24

|

72,97

|

77,0

|

54

|

12

|

34

|

28

|

0,28

|

|

25

|

76,00

|

80,0

|

57

|

12

|

36

|

28

|

0,30

|

|

30

|

91,12

|

95,0

|

60

|

12

|

38

|

30

|

0,45

|

The suitable chain 06B-1 stainless steel similar to DIN 8187 you will find here.

- ISO-No.: 06B-3 (3/8“ x 7/32“)

- pitch: 9,52 mm

- inner width: 5,72 mm

- Roller-diameter: 6,35 mm

- Tooth width bf3 25,6 mm

- ba 1,0 mm (radius width)

- rx 10 mm (min. tooth radius)

| No. of teeth |

pitch circle |

tip circle |

hub |

pilot bore |

bore |

total |

weight |

|

Ø |

Ø |

Ø |

Ø |

max. |

length |

approx |

| z |

d0 |

dk |

dn |

d1 |

d2 |

L |

kg |

| Material steel/C45 |

|

|

|

|

|

|

|

| 8 |

24,89 |

28,0 |

15 |

6 |

9 |

32 |

0,05 |

| 9 |

27,85 |

31,0 |

18 |

8 |

11 |

32 |

0,07 |

| 10 |

30,82 |

34,0 |

20 |

10 |

12 |

32 |

0,09 |

| 11 |

33,81 |

37,0 |

22 |

10 |

14 |

35 |

0,11 |

| 12 |

36,80 |

40,0 |

25 |

10 |

16 |

35 |

0,15 |

| 13 |

39,79 |

43,0 |

28 |

10 |

18 |

35 |

0,19 |

| 14 |

42,81 |

46,0 |

31 |

12 |

20 |

35 |

0,23 |

|

|

|

|

|

|

|

|

| 15 |

45,81 |

49,3 |

34 |

12 |

22 |

35 |

0,28 |

| 16 |

48,82 |

52,0 |

37 |

12 |

23 |

35 |

0,33 |

| 17 |

51,84 |

55,0 |

40 |

12 |

25 |

35 |

0,39 |

| 18 |

54,85 |

58,0 |

43 |

12 |

27 |

35 |

0,45 |

| 19 |

57,87 |

61,0 |

46 |

12 |

28 |

35 |

0,51 |

|

|

|

|

|

|

|

|

| 20 |

60,89 |

64,0 |

49 |

12 |

31 |

35 |

0,58 |

| 21 |

63,91 |

68,0 |

52 |

14 |

32 |

40 |

0,70 |

| 22 |

66,93 |

71,0 |

55 |

14 |

34 |

40 |

0,78 |

| 23 |

69,95 |

74,0 |

58 |

14 |

36 |

40 |

0,87 |

| 24 |

72,97 |

77,0 |

61 |

14 |

38 |

40 |

0,97 |

|

|

|

|

|

|

|

|

| 25 |

76,00 |

80,0 |

64 |

14 |

41 |

40 |

1,06 |

| 26 |

79,02 |

86,0 |

67 |

14 |

42 |

40 |

1,17 |

| 27 |

82,05 |

86,0 |

70 |

14 |

44 |

40 |

1,27 |

| 28 |

85,07 |

89,0 |

73 |

14 |

45 |

40 |

1,39 |

| 29 |

88,09 |

92,0 |

76 |

14 |

47 |

40 |

1,50 |

|

|

|

|

|

|

|

|

| 30 |

91,12 |

95,0 |

79 |

14 |

49 |

40 |

1,62 |

| 31 |

94,75 |

98,3 |

80 |

16 |

50 |

40 |

1,72 |

| 32 |

97,18 |

101,0 |

80 |

16 |

50 |

40 |

1,80 |

| 33 |

100,20 |

104,3 |

80 |

16 |

50 |

40 |

1,89 |

| 34 |

103,20 |

107,3 |

85 |

16 |

53 |

40 |

2,06 |

|

|

|

|

|

|

|

|

| 35 |

106,26 |

110,0 |

85 |

16 |

53 |

40 |

2,15 |

| 36 |

109,29 |

113,0 |

90 |

16 |

56 |

40 |

2,33 |

| 37 |

112,32 |

116,4 |

90 |

16 |

56 |

40 |

2,43 |

| 38 |

115,34 |

120,0 |

90 |

16 |

56 |

40 |

2,53 |

| 39 |

118,30 |

122,0 |

90 |

16 |

56 |

40 |

2,63 |

|

|

|

|

|

|

|

|

| 40 |

121,40 |

125,5 |

90 |

16 |

56 |

40 |

2,74 |

|

|

|

|

|

|

|

|

| 38 |

115,34 |

119,0 |

90 |

23 |

56 |

56 |

3,15 |

| material: GG-22 |

|

|

|

|

|

|

|

| 45 |

136,50 |

141,0 |

90 |

23 |

56 |

56 |

3,56 |

| 57 |

172,91 |

177,0 |

90 |

23 |

56 |

56 |

3,97 |

| 76 |

230,49 |

235,0 |

100 |

23 |

64 |

56 |

4,52 |

| 95 |

288,02 |

292,7 |

100 |

23 |

64 |

56 |

6,12 |

| 114 |

345,68 |

350,3 |

100 |

23 |

64 |

56 |

7,45 |

racks for sliding gates

racks for sliding gates

| racks for sliding gates |

nominal length

|

|

height |

tooth width

|

weight |

| module |

in mm |

|

|

|

approx |

| |

L |

ho |

ha |

B |

kg/St. |

| module 4,0 |

1005 |

26 |

30 |

12 |

1,20 |

- pitch 12,566mm

- module 4

- straight toothing

- angle of pressure 20°

- material C45

- surface: zinc plating

- including 3 distance bushing

| Teilung |

|

|

|

|

|

|

|

W |

T1 |

T2 |

Ø |

B |

T3 |

| mm |

mm |

mm |

mm |

mm |

mm |

mm |

| 101,6 |

36 |

12 |

30 |

14 |

14 |

8 |

| 101,6 |

36 |

8 |

24 |

14 |

10 |

6 |

| 102 |

36 |

12 |

28 |

14 |

14 |

8 |

| 102 |

36 |

8 |

25 |

14 |

10 |

6 |

| 125 |

36 |

13 |

30 |

16 |

14 |

10 |

| 142 |

50 |

28 |

62 |

25 |

30 |

15 |

| 142 |

50 |

25 |

54 |

25 |

27 |

15 |

| 142 |

50 |

19 |

42 |

25 |

20 |

11 |

| 160 |

50 |

23 |

50 |

25 |

25 |

13 |

| 200 |

60 |

30 |

66 |

30 |

32 |

20 |

| 200 |

60 |

25 |

55 |

30 |

27 |

16 |

| 260 |

75 |

31 |

70 |

32 |

33 |

20 |

| 260 |

75 |

31 |

65 |

32 |

33 |

20 |

| Teilung |

|

|

|

|

|

|

|

W |

T1 |

T2 |

Ø |

B |

T3 |

| mm |

mm |

mm |

mm |

mm |

mm |

mm |

| 216 |

72 |

26 |

64 |

35 |

28 |

20 |

| 216 |

72 |

25 |

58 |

35 |

27 |

18 |

standard available in following materials:

20MnCr5 Case Hardening

16MnCr5 Case Hardening

C40 Hardening & Tempering

42CrMo4 Hardening & Tempering

Pin:

20MnCr5

16MnCr5

C40

SS 420

SS 304

circlip:

St 37.2

SS 420

SS 304

We welcome your own Design or other Dimensions! ask us!

| K |

pitch |

Pin- |

Between |

Sidebar |

Sidebare |

Overall |

Breaking |

weight |

|

|

Diameter |

Sidebars |

Thickness |

Height |

Width |

Load |

|

| Chain- |

|

|

|

|

|

|

|

|

| No. |

p |

D6 |

L |

S |

H |

F |

kN |

kg/m |

|

mm |

mm |

mm |

mm |

mm |

mm |

|

ca. |

| X348 |

76,60 |

12,70 |

19,10 |

27,00 |

12,70 |

44,50 |

101 |

3,28 |

| X458 |

102,40 |

15,90 |

26,20 |

34,90 |

15,90 |

57,20 |

218 |

4,80 |

| X678 |

153,20 |

22,20 |

33,30 |

50,10 |

22,20 |

76,20 |

420 |

9,98 |

| 698 |

153,20 |

22,20 |

39,70 |

68,30 |

25,40 |

95,30 |

600 |

17,00 |

| 998 |

229,40 |

28,60 |

39,70 |

68,30 |

98,40 |

95,30 |

600 |

13,40 |

| K |

|

|

|

|

permissible |

permissible |

Test load

|

weight |

|

pitch |

|

|

|

tooth width

|

operating load |

|

|

| Chain- |

p |

A |

D |

E |

|

|

|

q |

| No. |

mm |

mm |

mm |

mm |

mm |

kg |

kg |

kg/m |

|

|

|

|

|

|

max. |

min. |

ca. |

| 42 |

42 |

60 |

9 |

24,5 |

16 |

360 |

1800 |

4,5 |

| 59 |

59,5 |

69 |

9 |

29 |

20 |

460 |

2300 |

4,2 |

| 63 |

63 |

68 |

10 |

29 |

20 |

480 |

2400 |

4,2 |

| 65 |

65,5 |

80 |

12 |

26 |

23 |

760 |

3800 |

6,8 |

| 85 |

85 |

86 |

14 |

33 |

24 |

800 |

4000 |

7,7 |

| 87 |

87 |

108 |

17 |

45,5 |

32 |

1000 |

5000 |

12,0 |

| 100 |

100 |

75 |

12 |

32 |

23 |

600 |

3000 |

4,4 |

| 100 A |

100 |

79 |

13 |

28 |

23 |

640 |

3200 |

5,5 |

| 100 B |

100 |

118 |

15 |

40 |

32 |

900 |

4500 |

9,0 |

| 100 D |

100 |

118 |

17 |

28 |

23 |

1320 |

6600 |

11,3 |

| 135 |

134,5 |

100 |

12 |

33,5 |

24 |

640 |

3200 |

4,1 |

| 135 A |

135 |

108 |

15 |

33 |

24 |

700 |

3500 |

5,0 |

| 136 |

136,5 |

124 |

17 |

30,5 |

27 |

1200 |

6000 |

9,5 |

| nominal thickness |

distance of attachment |

attachment-dia. |

| 4,40 |

50 |

34 |

| 4,90 |

70 |

40 |

| 4,90 |

70 |

46 |

| article- |

thickness |

pitch |

inner width |

weight |

load capacity (Z) |

| No. |

d |

p |

a |

kg / 100m |

kN |

| KK-1,4* |

1,4 |

20 |

17,2 |

4,2 |

14 |

| KK-1,6* |

1,6 |

23 |

19,8 |

5,9 |

16 |

| KK-1,8* |

1,8 |

25 |

21,4 |

7,3 |

20 |

| KK-2,0* |

2,0 |

28 |

24,0 |

8,7 |

25 |

| KK-2,2* |

2,2 |

31 |

26,6 |

10,8 |

35 |

| KK-2,5* |

2,5 |

35 |

30,0 |

14,1 |

45 |

| KK-2,8* |

2,8 |

39 |

33,4 |

17,0 |

65 |

| KK-3,1* |

3,1 |

41 |

34,8 |

21,0 |

75 |

| KK-3,4* |

3,4 |

44 |

37,2 |

26,0 |

95 |

| KK-3,8* |

3,8 |

46 |

38,4 |

34,0 |

110 |

*SS for stainless steel or ZP for zinc plated

|

|

inner width

|

Roller- |

Pin- |

Plate- |

Plate- |

Pin- |

|

breaking |

weight |

|

pitch |

inner link |

dia. |

dia. |

height |

thickness |

length |

|

load |

|

| Chain- |

p |

b1 |

d1 |

d2 |

g |

s1/s2 |

l 1 |

Le |

FB |

q |

| o. |

|

mm |

mm |

mm |

mm |

mm |

mm |

mm |

kN |

kg/m |

|

mm |

min. |

max. |

max. |

max. |

max. |

max. |

|

min. |

approx |

| ST131 |

133,330 |

27,00 |

80,00 |

24,00 |

50,0 |

5,0 |

54,5 |

394 |

180,00 |

9,00 |

| T131 |

133,330 |

27,00 |

80,00 |

14,63 |

40,0 |

5,0 |

55,0 |

394 |

180,00 |

6,35 |

| ST133 |

133,330 |

27,00 |

70,00 |

14,63 |

40,0 |

5,0 |

54,8 |

400 |

180,00 |

7,70 |

| ST133Z |

133,330 |

27,00 |

80,00 |

24,00 |

40,5 |

5,0 |

54,5 |

400 |

180,00 |

8,54 |

|

|

inner width |

Roller- |

Pin- |

Plate- |

Plate |

Pin- |

breaking |

weight |

|

pitch |

inner link |

dia. |

dia. |

height |

thickness |

length |

load |

|

| Ketten- |

p |

b1 |

d1 |

d2 |

g |

s |

a |

FB |

q |

| no. |

|

mm |

mm |

mm |

mm |

mm |

mm |

kN |

kg/m |

|

mm |

min. |

max. |

max. |

max. |

max. |

max. |

min. |

approx |

| PT131 |

131,330 |

27,00 |

70,00 |

14,63 |

40,0 |

5,0 |

55,0 |

180,00 |

5,98 |

|

|

inner width

|

Pin- |

Plate- |

Plate- |

Pin- |

|

|

|

breaking |

|

pitch |

inner link |

dia. |

height |